Features : All windings are made by experienced and qualified winders with at least 2 years of experience.

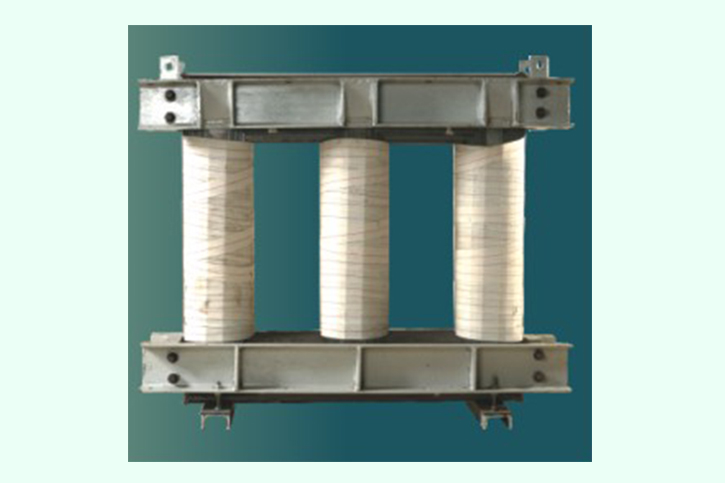

Dry type windings are made on fibre glass mandrels to ensure there is no inadvertent tearing of the insulations.

All windings are designed to withstand short circuit and to minimize copper usage.

Windings are made using either copper or aluminium, and can be offered for oil filled transformers, VPI dry type transformers or cast resin transformers.

Features : Core used is grain oriented steel and manufactured and designed considering the Step Lap method, including mitred joints.

Using optimal design and manufacturing, air gaps are reduced between yokes and legs for reducing noise &losses.

Core is bound to reduce noise &losses.

Core is sourced from quality vendors to achieve best quality as well as ensure long life. Each core is inspected and losses measured PRIOR to next process.

Features : Windings are taken after consolidation and placed on individual limbs of cores.

Proper insulation scheme, spacers and routing of cables ensured.

Reblading, brazing of busbars and final fitting completed.

Core coil assembly is dried for over 12 hours at upto 105 degrees, until completely dry.

33kv and above are processed under vacuum.

Features : Fully dried and consolidated core coils are taken and inserted into tanks.

After tightening, fixing and cover closure, fittings and accessories are mounted.

Tanks are pressure tested for 4 hours in Hot Oil Condition.

Transformers are painted and paint thickness is checked and maintained.

Custom painting system according to customers requirements are offers in Epoxy, Hot Zinc Spray, Powder Coating and Polyurethane.

Features : All transformers are tested in our Lab to National and International Standards ( IS : 2026, IEC 76, etc. ) And IS 1180(Part I 2014).

Voltage ratio

Winding resistance

Impendence voltage

No load and load losses

No load current

Dielectric tests

Noise level measurement

DGA - Dissolved Gas Analysis for testing oil

Harmonic measurement and analysis

Temperature rise test plant

Vacuum and pressure test plant

Oil test facilities

Specific type tests at approved laboratories can be offered such as Measurement of zero sequence impedance

Lighteningimpulse test

Dynamic short circuit test